NOTÍCIAS

15 de Agosto de 2025 às 18:23

What are rare earths and how can they drive energy transition in the country?

The country has the 2nd largest reserve in the world, but 0.02% of production. The project with SENAI Innovation Institutes and 28 companies wants to meet national demand, which should increase sixfold by 2034.

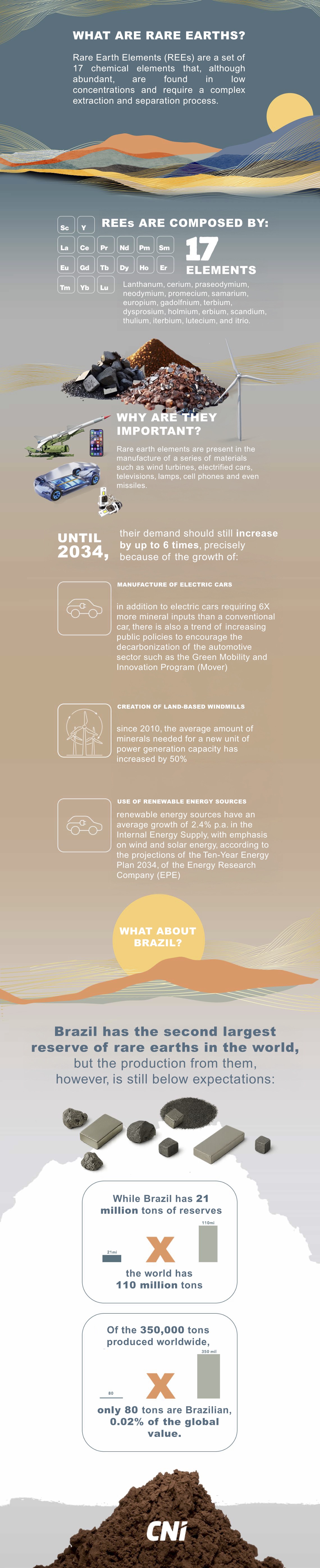

Essential for manufacturing of wind turbines, engines for electric vehicles and electronic equipment, Rare Earth Elements (REEs) are a set of 17 chemical elements that, although abundant, are found in low concentrations and require a complex extraction and separation process until they become permanent alloys and magnets – the final product most used by the industry in energy transition.

Like other critical and strategic minerals, REEs are at the center of geopolitical negotiations, since their reserves and production are under the control of few countries.

In the case of Rare Earths, China holds about 40% of reserves and 70% of production, hegemony conquered since the 2000s, but with investments that began 40 years ago. When it comes specifically to manufacturing magnets from REEs, the Asian monopoly surpasses 90%.

Brazil has the second largest reserve (19%), but only 0.02% of world production: 80 tons of the 350,000 produced worldwide. Projections by the Energy Research Company (Empresa de Pesquisa Energética - EPE) indicate that the demand for REEs in the country is expected to grow by 6 times from 2024 to 2034, jumping from about 1,000 to over 6,000 tons.

"For geopolitical reasons, to guarantee the supply of raw materials, and because of electric mobility and renewable energies, the world began to further consider the importance of these elements. With the Paris Agreement, fleet electrification and wind energy began to be seen as strategies to reduce emissions", explains André Pimenta de Faria, coordinator of the rare earth magnets factory-lab, which is part of the SENAI Institute for Innovation in Mineral Processing, headquartered in Minas Gerais.

Meet the largest permanent magnet production plant in South America

The good news is that we are getting closer and closer to achieving autonomy in the industrial process. A pilot plant with the potential to produce 100 tons of permanent magnets a year is already operating at the Lagoa Santa (MG) laboratory. The factory will process the neodymium - one of the rare earth elements -, iron and boron (NdFeB) alloy to produce the magnets.

The Institute and six other research and technology institutions joined 28 companies to implement the complete cycle of national production, from elements extraction and refining to final production and recycling of magnets.

MagBras was one of the three projects approved in the last call for Structuring Projects by the Brazilian National Service for Industrial Training (SENAI) with the Supporting Foundation of the Federal University of Minas Gerais (Fundep), within the scope of the Mover Program. Their investment was of R$ 73.3 million, of which R$ 60 million are from Mover and R$ 13.3 million from the companies' counterpart.

The 28 involved comprise startups and companies from different segments, including Weg, Stellantis, Iveco Group, Vale, Mosaic and Schulz; in addition to the Technological Research Institute (IPT); the Mineral Technology Center (Cetem); the Federal University of Santa Catarina (UFSC); and the Senai Institutes of Innovation in Mineral Processing (MG), Laser Processing (SC), Manufacturing Systems (SC) and Advanced Manufacturing (SP). The great differential of the ambitious project is bringing together different actors in the chain and reference research institutions in the area.

"Today, there is a company operating with rare earths in Goiás. Production started in 2023, they are starting to grow. We also have laboratories, such as IPT, which produces alloys from oxide; and Magma, from UFSC, producing rare earth magnets. The differential of our institute's plant is to produce and validate in industrial scale", details André Pimenta de Farias.

The researcher recognizes that it is the largest plant for the production of magnets and rare earth alloys in terms of scale and structure in the Southern Hemisphere. With the approval of MagBras, the Institute's team should more than double, from 9 to 20 people, by the end of this semester.

In addition to competing with other countries that dominate technology and investments, he highlights hiring professionals as one of the biggest challenges. Knowledge is still concentrated in the academy, with masters and doctors, and specialists and technicians are needed to work on the plant's operation.

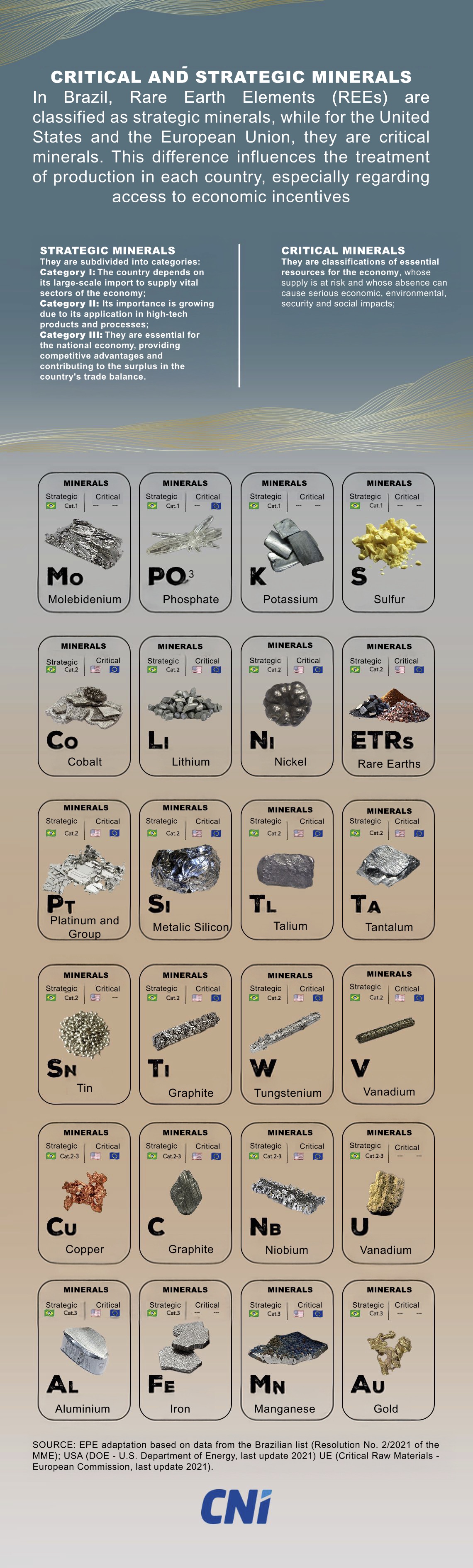

Rare earths consist of critical and strategic minerals

Rare earth elements are some of the so-called critical or strategic minerals, which include an extensive list such as copper, nickel, graphite, cobalt, niobium, and lithium. According to the Energy Research Company (EPE), minerals can have varying classifications depending on the country in question.

An example is niobium, considered a critical mineral by the European Union and the United States, while Brazil classifies it as a strategic mineral. This difference influences the treatment of production in each country, especially in access to economic incentives.

"Security and diversification of critical and strategic mineral supply chains in line with sustainability and economic development parameters are among the main objectives of public policies launched in recent years," says EPE's publication. Canada, the United States and the European Union have already outlined their strategies and are investing billions to ensure the necessary supplies for energy security and transition.

Understand the differences between critical and strategic mineral: